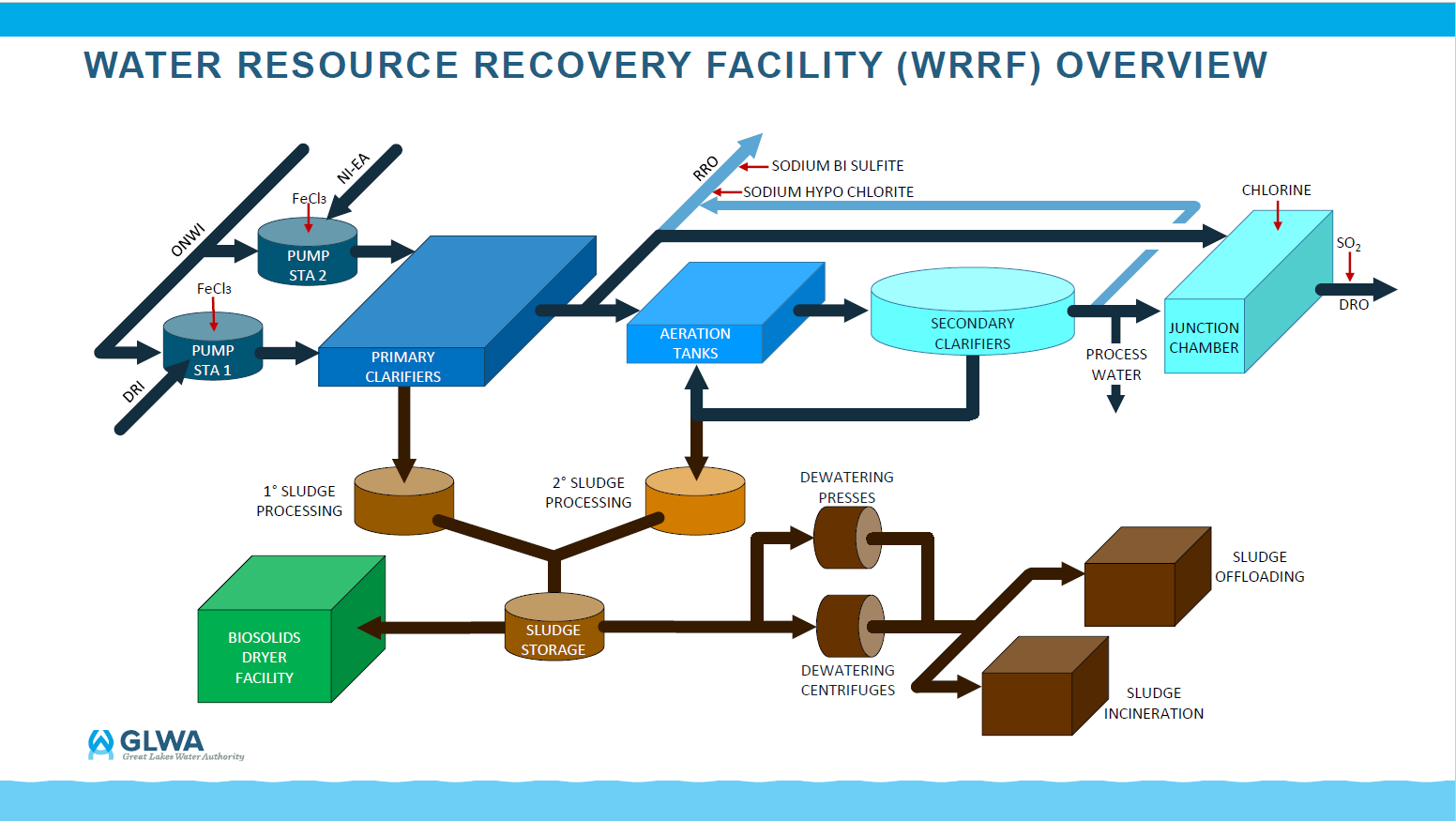

The Great Lakes Water Authority (GLWA) Water Resources Recovery Facility (WRRF) is one of the ten largest WWRF’s in the world. Treating wastewater and stormwater from a service area with a population of over 3 million, it accomplishes primary treatment, secondary treatment, and phosphorus removal using ferric chloride. The ferric chloride dose used is quite low by conventional standards, and WRRF staff have observed system behavior suggesting that, in addition to chemical phosphorus removal, the secondary treatment system also accomplishes biological phosphorus removal.

Characterizing the Performance and Operational Characteristics of the Bioreactors at the Detroit, Michigan, Water Resource Recovery Facility

Faculty advisor: Glen T. Daigger

Students: [2017-2018] Zheyi Tian (MS), Jin Yan (MS), Cheng Yang (MS)

[2018-2019] Ross Vander Meulen(MS), Chaoqun Cheng(MS),Tong Yu(MS),

Yuewei Liu(MS), Cheng Yang (PhD)

[2019-2020] Chaoqun Cheng(MS), Changyoon Jun(MS)

[2020- now] Changyoon Jun(MS), Cao Yi (MS)

Excessive phosphorus in waterways causes harmful algae blooms, a side effect of eutrophication, and water quality deterioration. Thus, the control of phosphorus in WRRF effluents is essential to both environmental and human health. Phosphorus removal by WRRFs is accomplished by converting soluble phosphorus to particulate phosphorus and subsequent removal of that particulate matter. This can be accomplished by both chemical and biological means. Chemical precipitation is used to remove the inorganic forms of phosphate by the addition of a metal salt (iron or aluminum), while the configuration of an activated sludge system can lead to conditions where a biological population develops that is capable of removing phosphate to levels beyond that simply required for biomass synthesis.

The objective of this project is to characterize and better understand the chemical and biological phosphorus removal occurring at the GLWA WRRF. Chemical addition for phosphorus removal results in costs for chemical purchase and additional sludge that must be processed, while operation of the bioreactors represents a significant cost for electricity and pure oxygen purchase. Better understanding the interaction between biological and chemical phosphorus removal can, thus, provide the basis for improved plant performance and cost reduction.

The Daigger research team is conducting a series of evaluations which have confirmed these observations, are further characterizing chemical and phosphorus removal at the GLWA facility, and are incorporating these results into a state-of-the-art treatment system process model. The near-term objective is to identify and characterize approaches to improve phosphorus removal performance while reducing resource (energy, chemicals) use. In the longer-term, this research provides the basis to assist GLWA to identify and implement approaches to significantly increase resource recovery at the facility.

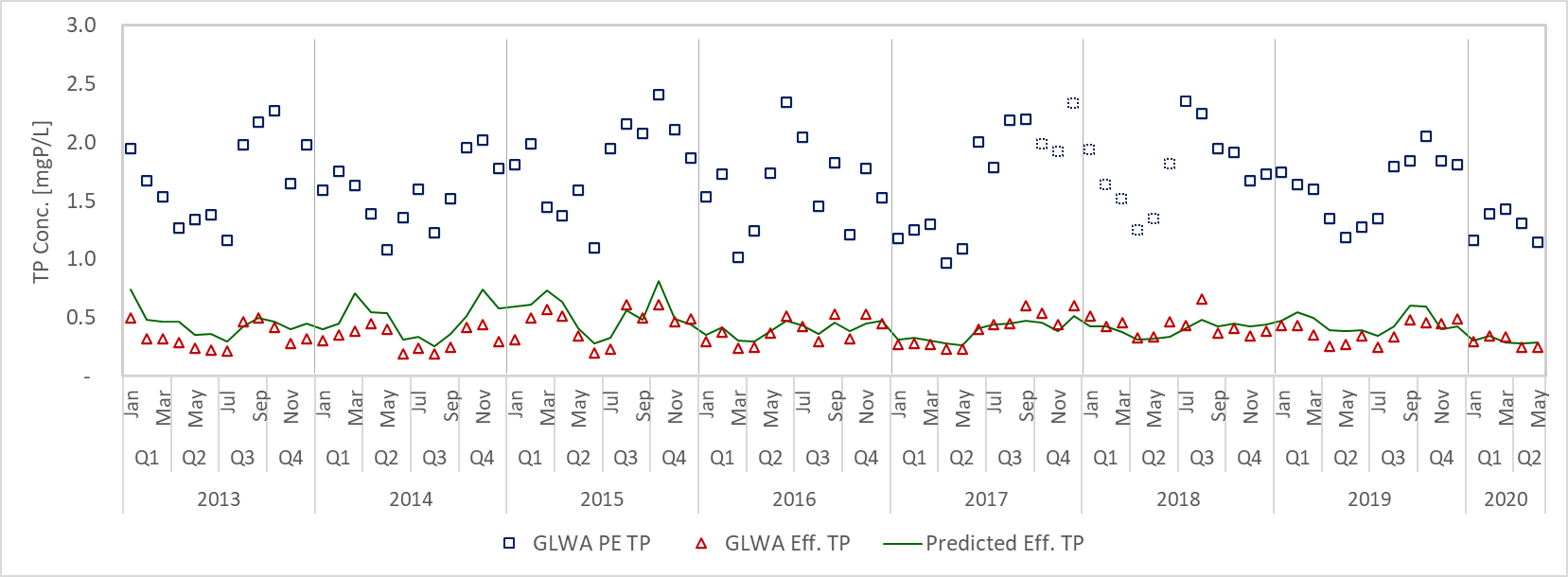

The Daigger research team has characterized chemical and biological phosphorus removal at the GLWA facility,and demonstrated that biological phosphorus removal occurs. The method by which biological phosphorus removal occurs is unique as the secondary process influent volatile fatty acid (VFA) concentrations are quite low and the mainstream anaerobic zone is not of sufficient size to generate sufficient VFA’s for the growth of a sufficient phosphorus accumulating organism (PAO) population. In this instance, fermentation to produce VFA’s occurring in the facility’s secondary clarifier has proven essential. Performance of the secondary treatment system has been fully characterized in a biological process model (SUMO, Dynamita) and used to examine operating and modest facility modifications to further enhance biological phosphorus removal. Results indicate that ferric chloride addition prior to secondary treatment could be terminated and the plant could continue to meet effluent phosphorus limits. GLWA is currently in the process of evaluating improvements to be implemented.

The recognized occurrence of biological phosphorus removal creates the possibility that the GLWA WRRF cannot only remove phosphorus from its influent wastewater stream, but to recovery phosphorus for reuse. Research to investigate this possibility is being developed.

Figure. Comparison of Historical GLWA Monthly Average Effluent TP with Monthly Average Calibrated Model Results.

Contact: [email protected]

Biological Phosphorus Removal Bench-Scale Testing at the Great Lakes Water Authority (GLWA) Water Resource Recovery Facility (WRRF), Detroit, Michigan

Faculty advisor: Glen T. Daigger

Master’s students: Ross Vander Meulen, Chaoqun Cheng

Following on initial work at the Great Lakes Water Authority (GLWA) Water Resource Recovery Facility (WRRF), bench-scale testing is being conducted using GLWA primary effluent without ferric chloride added to assess the full bio-P capacity potentially available for the existing secondary treatment system. GLWA is also running pilot tests on anaerobic digestion of waste sludges (primary, WAS, and imported organic matter), and conversion to full bio-P would significantly affect such a system. A process model of the GLWA liquid treatment process as part of the previous U-M research can be extended to include solids processing options, including the current system and various anaerobic digestion options including phosphorus recovery, to assist GLWA to understand the impacts of potential process modifications. Thus, the objectives of this research are to:

- 1. Determine the bio-P capacity of a biological process representing conversion of the existing HPO activated sludge process to bio-P and receiving primary effluent without upstream ferric chloride addition.

- 2. In collaboration with on-going anaerobic digestion research on-going at the GLWA WRRF, characterize the anaerobic digestability of the produced bio-P WAS using bio-methane formation potential (BMP) techniques.

- 3. Update the existing GLWA WRRF process model to incorporate bio-P with and without ferric chloride addition and solids processing options, including anaerobic digestion, and including impacts of solids handling recycle streams on plant performance.

Contact: [email protected]